How to reduce insect numbers in your factory in five simple steps

Wednesday 13th January 2021

Reducing customer complaints for insects.

Insect pests will crop up in food production and manufacture, it is the nature of the beast. The question is what to do about controlling insects and how you control them.

Dirty secret alert- a lot of pest control professionals really struggle with their knowledge of insects, their behaviour and biology. The results of the entry level examination in the pest control industry show that the great majority of candidates fail on the “Invertebrates” module. In my experience technicians tend to shy away from bugs because they are so much harder to understand and control than rats and mice.

As a result, lots of insect control contracts end up looking like this:

- Your contractor responds to requests for treatment when you see a spike in numbers but isn’t proactive.

- There are traps on site, and you get numbers reported, but they don’t really mean anything, and you rarely get an early heads-up on infestations.

- Your contract has a “threshold” number. Anything below this number you consider to be “safe,” anything above this number initiates an insecticidal treatment. Nobody knows where the number has come from or what was done to work it out.

I have outlined a few short steps below to show you how to reduce numbers of pest insects in a factory environment

- If there are already a lot of insects in your factory, you may have to start with a large scale “knockdown” treatment so you can start your programme with a blank canvas

- Use pheromone traps to find out where the insects are (and make sure you have enough of them!)

Don’t be fooled by the name. These insect traps are only there to indicate that there are insects in the area. They are not a method of control in themselves. Also, not all insect traps are created equal; some of them contain pheromones, which are the ones you want. Some of them only contain a food attractant, which can be less than attractive to an insect on a site that produces… food.

By and large, pest control companies don’t use nearly enough of these traps and the data from any area can be very patchy. You must be sure that the grid pattern of traps covers the entire production area and above all, make sure the grid is suitably 3D if you have production taking place on more than one level.

- Create an acceptable metric for your site and use it as a KPI. The metric should take into account the level of risk associated with each part of the process (egg closer to open food areas or out-loading is higher risk.) Make sure your pest controller has complete knowledge of your processes, where the CCP points are and reacts to insect numbers accordingly.

Do not accept the received wisdom that there should always be an ‘acceptable threshold’ or trigger.

- Combine cleaning and pest control efforts

No insect control plan should be entirely based on insecticidal treatments. Every pest control programme should be based on the foundations of directed hygiene efforts.

Often improving the knowledge of your cleaning and operations staff is key here. At Dealey we make sure our new customers all get unlimited access to our online learning portal for their ops team.

- Have insecticidal treatments targeted to their sources

If you must resort to insecticidal treatments, they should be driven by the data gleaned from your traps. No more Spray and Pray!

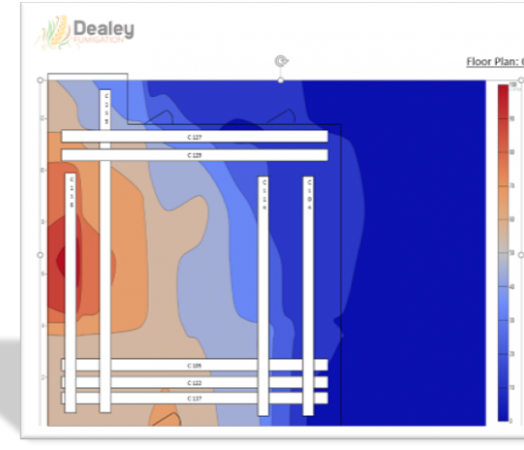

Often visual representations of the insect populations can be useful here. We use heat maps which often raise individual lines or machinery which requires attention. In this way you can limit the number of treatments you have, saving money, and cut the infestations off at source, reducing risk in the long run.

At Dealey we have developed the Insect 100 programme which has taken many years to develop and refine. It works across multiple sites and has an easy to follow calendar along with a stepped out plan for provable insect number reduction.

Call Dealey on 01359269713 for more information